Different Types of Wood Floor Gap Filling: Resin, Slivers, Dust Mix & More

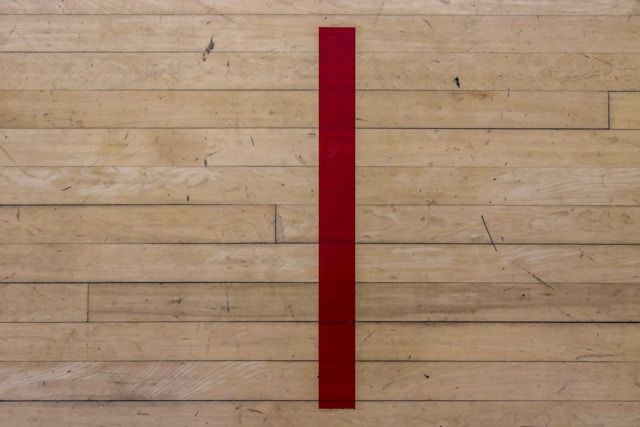

There’s a certain romance to an old wood floor—the warm patina, the gentle creaks, the whispers of history underfoot. Yet, that same character can be marred by the appearance of gaps between the planks. These fissures, born from seasonal wood movement, age, or changes in humidity, can be more than just an aesthetic nuisance. They can collect dust, weaken the floor's feel, and let drafts whisper through. But fear not, for the art of gap filling offers a solution. However, not all gaps are created equal, and the method you choose can mean the difference between a seamless repair and a costly mistake.

This article delves into the world of wood floor gap filling, exploring the unique characteristics, best applications, and pros and cons of each primary method. Whether you’re considering a DIY project or planning to call in the experts, understanding these options is the first step to restoring your floor's beauty and integrity.

What is Gap Filling?

Gap filling is the specialized process of filling the spaces between wooden floorboards to create a more uniform, solid, and visually cohesive surface. It's a crucial step in both restoring historic floors and maintaining newer ones, especially in environments with significant fluctuations in temperature and humidity that cause wood to expand and contract.

It’s essential to understand that gap filling is not about preventing natural wood movement—that’s impossible. Instead, it’s about managing its visual and practical consequences. A proper fill bridges the space while remaining flexible enough to accommodate future movement without cracking or dislodging. The goals are clear: to enhance aesthetics, improve cleanliness by eliminating dust traps, increase thermal insulation, and provide a smoother, more even walking surface.

Types of Gap Filling: Materials and Methods

Choosing the right filler depends on the gap size, floor type, wood species, desired finish, and the floor's future environment. Here’s a breakdown of the most common solutions.

Resin Fillers (Two-Part Epoxy or Polyurethane)

These are modern, highly durable solutions for medium to large gaps.

- How it works: A two-part resin and hardener are mixed, often with fine sanding dust or colored pigments to match the wood. The viscous liquid is poured or troweled into gaps, where it cures into an extremely hard, water-resistant plug.

- Best for: Wide gaps (3mm and above), parquet floors, commercial spaces, and areas requiring high hygiene (it creates a seamless, non-porous surface).

- Pros: Extremely durable and stable; can be sanded flush; excellent moisture resistance; creates a modern, monolithic look.

- Cons: Permanent and inflexible; can be visible if color match is poor; difficult to remove if the floor needs significant future movement; application is messy and requires skill.

Wood Slivers (or Shims)

The traditional, craftsman-approved method for authentic restoration.

- How it works: Thin slivers of matching wood species are custom-cut, glued, and gently tapped into the gap. Once set, they are planed and sanded perfectly flush with the floor.

- Best for: Historic floor restoration, wide gaps in solid wood floors, and situations where a perfect, natural wood repair is desired.

- Pros: Uses the same material as the floor, ensuring a perfect grain and color match; moves naturally with the floor; ages consistently; highly aesthetic and authentic.

- Cons: Labor-intensive and time-consuming; requires significant skill in woodworking; generally the most expensive option; not ideal for tiny gaps.

Dust-and-Binder Mix (Sawdust & Finish)

A classic, time-tested method for small hairline cracks.

- How it works: Fine sanding dust collected from the actual floor is mixed with a binding agent—traditionally shellac or lacquer, but now often wood glue or a clear resin. The putty-like mixture is worked into the gaps, then sanded smooth.

- Best for: Small gaps (1-2mm) in unfinished floors that are about to be sealed and coated.

- Pros: Perfect color match as it uses the floor's own wood; cost-effective; good for DIY on small projects.

- Cons: Not very flexible; can shrink or fall out over time if not mixed correctly; not suitable for pre-finished or already oiled/waxed floors (adhesion issues); unsuitable for large gaps.

Other Methods & Flexible Fillers

- Acrylic Latex Wood Putty: Pre-mixed, user-friendly pastes for small repairs in stable environments. Best for minor touch-ups, not for large-scale gap filling, as they can shrink and lack flexibility.

- Rope Fill (Oakum): A historic method where tarred or waxed rope is hammered into wide gaps. It's flexible, rustic, and ideal for cottage-style or barn-style floors where a perfect seal isn't the goal.

- Flexible Silicone/Polymeric Fillers: Specialized products designed to remain elastic, moving with the floor. They are excellent for floors with extreme seasonal movement but can be difficult to finish and are not always paintable.

Why It's Best to Trust the Professionals

While filling a single gap might seem straightforward, a whole floor presents complex challenges best left to seasoned professionals. Here’s why:

- Accurate Diagnosis: A pro will determine the cause of the gapping (humidity issues, structural problems) before treating the symptom. Filling gaps without addressing the root cause is a temporary fix.

- Material Science Expertise: They understand how different fillers interact with various wood species, finishes, and environmental conditions. Choosing the wrong filler can lead to cracking, discoloration, or even restrict necessary wood movement, causing further damage.

- Mastery of Technique: Each method requires specific skills. Pouring resin level, cutting and fitting a wood sliver invisibly, or mixing a perfect dust blend are arts honed by experience. A botched job can be more unsightly than the original gaps.

- Color Matching Alchemy: Achieving a color that blends seamlessly, both when wet and as it ages, is incredibly difficult. Professionals have the experience and pigment libraries to create near-invisible repairs.

- Efficiency and Equipment: They have the right tools—from specialized gap saws and planes to industrial sanders and application systems—to complete the job efficiently and to a high standard, saving you time and potential frustration.

- Long-Term Guarantee: A reputable professional will offer a guarantee on their work, providing peace of mind that the repair will last.

Conclusion

Gaps in a wood floor are not a death sentence; they are a call for a thoughtful restoration. From the high-tech permanence of resin to the timeless craftsmanship of wood slivers and the simplicity of a dust mix, each filling method has its place in the wood floor specialist’s toolkit. The key to success lies in matching the right solution to the specific floor, its history, and its environment.

For a result that honors the beauty of your wood and stands the test of time, partnering with a skilled professional is an invaluable investment. They transform the functional act of filling a crack into a seamless restoration, ensuring your floors continue to tell their story—quietly, beautifully, and without a draft. Remember, a perfectly filled floor doesn’t just look restored; it feels solid, silent, and complete under every step.