Wooden floor sanding

The wooden floor is aesthetically pleasing, cozy and comfortable. It is not difficult to take care of it and its repair does not require huge efforts. The service life is reduced if the floor undergoes heavy loads. The easiest way to return the wooden substance to its original appearance, use a floor sanding.

What is a Floor Sanding?

Sanding is the removal of the top layer from the wood boards, on which scratches and scuffs accumulate. It is carried out with the help of a special tool – a sanding machine, because of which the process has acquired this name. The sanding includes three types of wood processing – sanding, polishing, and varnishing the floor.

The Sanding Process of the Wooden Floor

The peculiarity of the sanding machine is that it cannot be used indefinitely. With each procedure, the wooden layers are reduced. And although this may happen in 40-50 years, still do not abuse the procedure of sanding.

How to Determine That Sanding is Already Necessary?

- Mechanical damage of some boards;

- Stains that are not removed by conventional methods;

- Erasing the paint-and-lacquer coating;

To start the sanding process, you need to stock up on the following tools:

What Tools Will You Need

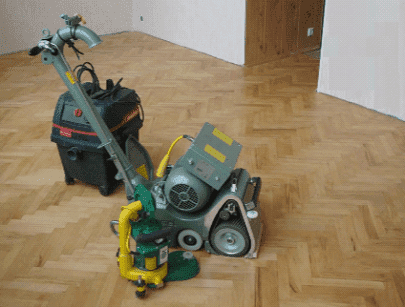

- Sanding machine;

- Main attachment;

- Attachment for hard-to-reach places;

- Vacuum cleaner for construction and repair work;

- An extension cord that will allow you to get all the corners of the repaired room with a sander

The Tools Used for Sanding Process of Wooden Floors

You should approach to the choice of a sanding machine with special attention. It can be of two types: drum and disc.

The drum tool is designed for the primary processing of the floor. It is characterized by large dimensions, noise in the process of operation. Due to the weight of the device, it is only used to remove the old surface. In addition, to use it, you need to get used to it – it is clumsy and requires experience to operate.

The next step is to use disc sanding machine. It is the disc tool that achieves the best quality of floor sanding. This tool is used by professional repair teams.

Preparation for the Start of Work

The first thing that is important to do before starting work is to inspect the entire floor. Note all existing defects, including the size of gaps and cracks.

It is also important to consider the humidity of the floor. To do this, you will need a special moisture measuring device. If the device shows that the amount of moisture in the wood exceeds the permissible norms, then the floor sanding should be carried out after opening the floor and completely drying it

Another important point – it is worth checking the coating for the bark beetle presence. It leaves small holes in the boards and wood dust around them. If traces of the beetle are found, the floor must also be opened before carrying out the work on the floor sanding.

If the two phenomena described above are not detected, you can proceed to the preparatory stage of sanding.

- Remove all items from the room to be repaired, including, if possible, removing the baseboards and removing the door. Nothing should interfere with the penetration of hard-to-reach places.

- Before removing the top coat of paint from the floor, it is important to examine it for strong cracks or mold.

- The windows in the room should be open, and the door can be covered with a thick film to prevent dust from entering other rooms.

- Floors are cleaned with normal clean water and left to dry completely.

- There should be no protruding boards or nails, they should be removed before starting work.

Safety Precautions During the Work

Sanding equipment requires special handling, as it can cause harm to humans if handled incorrectly.

- First, you need to wear clothes that do not interfere with work. There should be no hanging parts, and the hair should be removed – they can get into the sander, which will lead to injuries. Protective industrial clothing is ideal for work. It is a comfortable work wear made of light fabric that does not restrict movement. To avoid inhaling dust and dirt, it is important to wear a respirator or a normal safety protective mask.

- Secondly, it is important to keep an eye on the extension cord. If it gets under the tool, it can damage the wood or short-circuit the equipment itself. If this still happens, you must immediately pull the plug from the network.

- And, thirdly, the use of a sanding machine requires special skills. Otherwise, there is a chance to completely spoil the floor.

Stages of Wood Floor Sanding

After the preparation of the room, you can start the sanding itself.

- Remove the old coating. To do this, use a coarse-grained sanding sheet. At this stage, it is recommended to use a drum sanding machine. Before turning on the device, we tilt it slightly towards us, and then gently lower it. When the equipment starts, it will immediately become more difficult to keep it, so you should not be distracted from work. Removal is carried out from one wall to another, in a straight line. If the boards on the floor are placed strictly vertically, then the tool should walk diagonally – this way the varnish will be removed faster and better over the entire surface.

- At this stage, it is necessary to close all the cracks and gaps with a specialized filling putty. Allow it to dry completely and once again sand over the entire surface.

- Next, we treat the surface with disc machines to achieve maximum grinding quality.

- The next step is to carry out near the walls sanding. An angle grinder is ideal for this purpose. It is several times smaller than the classic device. We also go through hard-to-reach places and corners. To do this, it is better to use a manual sander.

- We vacuum the room.

- Now we apply varnish as the final layer. To fix the result, it is recommended to apply 3 or 4 layers. Each subsequent layer is applied after the previous one has completely dried.

Tips for the Floor Sanding

There are several tips that will make sanding faster and better:

- It is always necessary to start sanding with coarse-grained sanding sheets;

- Construction dust and varnish are highly flammable substances, so it is necessary to clean the room regularly;

What are the Main Advantages of Ordering the Professional Wood Floor Sanding?

- Complete professional surface inspection before starting work;

- New and modern equipment;

- Compliance with all safety requirements and standards;

- Low cost of all works involved compared to the obtained result.